All electrical systems and electrically energized equipment are potentially hazardous, whether Alternating Current (AC) or Direct Current (DC), whether 50 volts, 120 volts or higher. Therefore, electrical equipment should only be used for its intended purpose and only qualified personnel with the appropriate technical knowledge should perform electrical work.

General safeguards

- Properly maintain all electrical equipment and wiring. Visually inspect the condition of the plug, cable, and equipment for any signs of excess wear, frayed cables or exposed current-carrying parts. DO NOT USE any equipment that is damaged.

- Verify all equipment is in the OFF position prior to plugging or unplugging to avoid creating an arc at the receptacle. Wear protective gloves to avoid injury from a possible flash created by a short-circuit in the equipment.

- Do not pull on the cord when unplugging equipment. This can cause one or more of the wires to pull out of its termination in the plug. Always grasp the plug firmly to unplug.

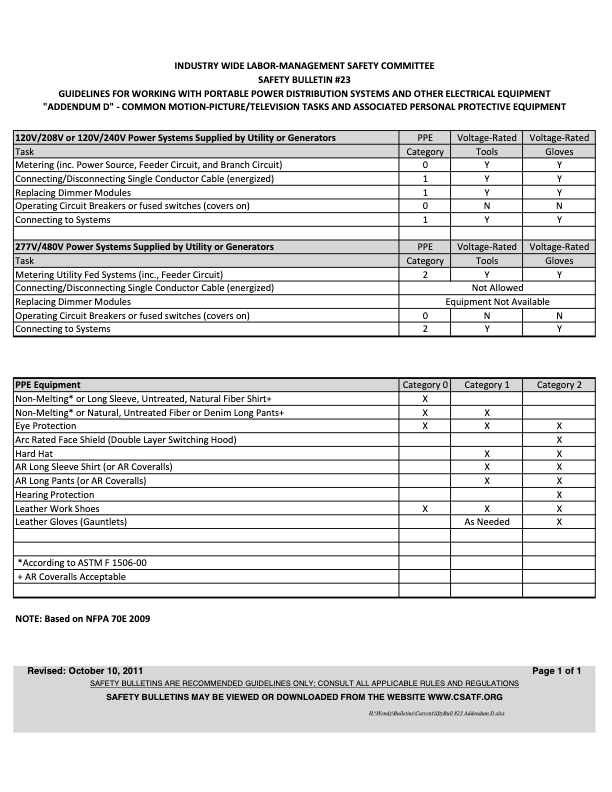

- All persons working on or near energized electrical equipment shall wear Personal Protective Equipment (PPE) appropriate for the level of electrical hazard to which they are exposed. This PPE may include non-melting, long-sleeved shirts and long pants, or other Arc Rated (AR) clothing, and closed-toed, nonconductive-soled shoes and Safety Glasses. Garments made from synthetic materials not manufactured specifically for electrical work, such as polyester and nylon, are not suitable to protect from electrical hazards.

Alternating Current and Direct Current

- When using both AC and DC systems in the same location, each system must be clearly identified as AC or DC. Always verify that you are not plugging AC equipment into DC systems or DC equipment into AC systems.

- All AC electrical systems shall be grounded. All grounded equipment should be tested for continuity between the ground pin on the plug and the metal parts of the equipment before it is put into service. In addition, all cables should be tested for continuity of the ground, neutral and phase conductor

Connecting to house power (tie-in)

- Connecting to a premises/house electrical power source, such as a panel board or switchboard, can create the risk of a serious or fatal accident. Such connections shall only be made by a qualified person.

- Connecting to an energized system is strongly discouraged. Always consider exposed electrical parts to be energized until you have verified they have been de-energized and locked out/tagged out.

- Keep electric panels accessible at all times. There should be no obstructions or storage within three feet (3’) of a panel. Fuses should only be replaced by qualified personnel. When replacing a blown fuse, be sure to select a fuse of proper voltage, interrupting capacity, and amperage for the application.

- Prior to a qualified person connecting to a premises/house electrical power system, the following requirements, among others, must be adhered to:

- Determine if the electrical system voltage is compatible with the equipment to which it will be connected.

- Calculate the electrical panel’s existing maximum ampere load to determine if the remaining capacity is sufficient for the additional equipment being connected.

- Use a properly sized circuit breaker or fusible disconnect switch to connect a distribution system to the premises/house electrical power system.

- The rated interrupting capacity of the circuit breaker or fuses must meet the available interrupting capacity at the point of connection to the premises/house electrical power system.

- Use only approved lugs or devices to connect to the panel bus.

- Never use “Alligator” type clamps.

- Never connect ahead of the main circuit breaker, fuse box, or meter.

- If required, obtain a permit to remove a panel cover.

- Use suitable barriers, partitions, or other means to limit access to the connection to protect against accidental contact with energized parts and unauthorized entry into the arc-flash boundary by unauthorized persons or objects.

- Replacement of all panels, covers and screws must be done by a qualified person immediately after disconnecting from the premises/house electrical power system.

Generators

- Only a qualified operator shall operate a generator. Approach to exposed connections on portable and vehicle mounted generators should be physically restricted or barricaded to non-qualified persons.

- The generator should have as much open space as possible on all sides to allow maximum ventilation and minimum interference. Make sure exhaust fumes are ventilated away from enclosed areas, personnel, and air intake ducts, such as trailers and buildings. Be aware of hot surfaces when working around a generator. It is important that all generating sets be protected from the elements and from unauthorized access.

- A fire extinguisher specific for the generator unit must be present and readily accessible outside the generator enclosure.

Location and environmental considerations

- Cables and devices should be protected from water and from foot and vehicle traffic damage. Electrical distribution systems should be elevated in such a manner that they will not come in contact with running or standing water. When it is necessary to have electrical distribution systems and devices which come into contact with water, such systems shall be designed and listed for use in water.

- Remember that lights placed too closely to props, sets and other materials may pose a fire risk and, therefore, make sure that lights are placed far enough away to alleviate risk.

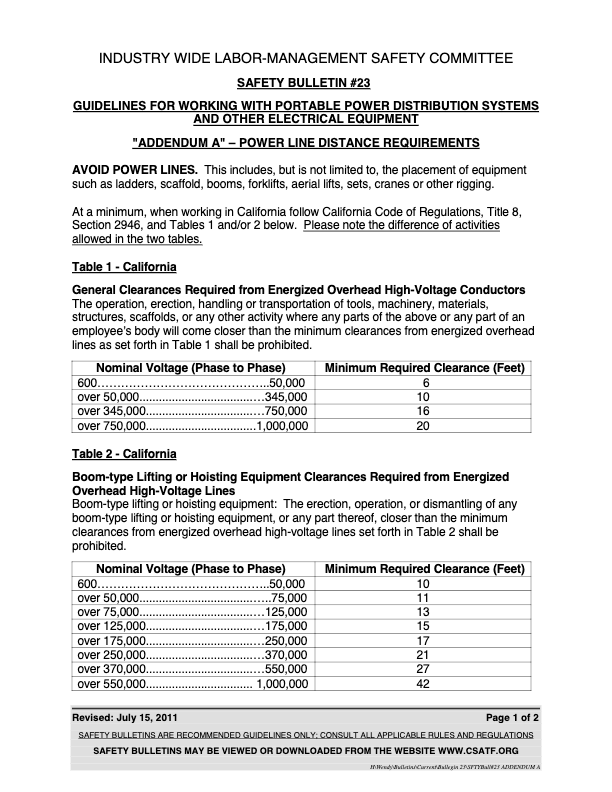

- Overhead clearances must be observed and maintained at all times. This applies to ladders, scaffolds, booms, forklifts, aerial lifts, scissor lifts, cranes, rigging, sets, truss work, backdrops and other equipment that could come in contact with power lines.

- To prevent electrocutions and injury resulting from contact between overhead power lines and conductive tools, materials, or scaffolds, OSHA recommends that employees be informed that most overhead, high voltage power lines are not insulated and, when in doubt, employees should assume that power lines are not insulated.

- Employers should notify the utility company when work must be performed under and/or near overhead power lines where clearances cannot be maintained. In such situations, utility companies should de-energize the power lines or temporarily move or cover them with insulating hoses or blankets before any work is initiated.

Emergency Response

- If an electrical accident occurs, notify emergency medical personnel and activate the Emergency Action Plan.

- An Emergency Action Plan should include the following items:

- Location, method and any necessary tools required for emergency power disconnection

- Emergency Medical Services on hand or readily available with working means of contact

- Exact location of where the work is being performed

- Identification of CPR Trained Personnel

- Location of available AEDs

- Do not approach any electrical accident until you have been notified by qualified personnel that it is safe to approach.

- Properly secure the accident area while maintaining a safe distance to prevent the possibility of additional victims.

- DO NOT touch or approach a victim of electric shock while he or she is being shocked. If safe to do so, turn off the power.

- Trained personnel should follow proper procedures for Cardiopulmonary Resuscitation (“CPR”) and Automated External Defibrillator (“AED”) use.

- Since the possible effects of electrical shock can manifest hours after the event, any victim of electric shock must be evaluated by a qualified medical professional.