Safety Bulletin

Guidelines

These guidelines pertain to the safe assembly and usage of powered and manually operated, counterbalanced camera cranes used for the purpose of television and film production. This Safety Bulletin may also be applicable to jib arms and similar types of units. Please consult Safety Bulletin: Camera Cars when camera cranes are used in conjunction with insert cars, tow dollies or process trailers.

- Each camera crane should be accompanied by an assembly/usage manual supplied by the manufacturer/vendor. The manual should clearly show assembly instructions, maximum payload and maximum gross weight in all configurations, safety precautions and maintenance procedures. Where different, manufacturer’s/vendor’s instructions shall supersede this Safety Bulletin. Read and follow all manufacturers’ placards on the equipment.

- Only persons trained in the safe use of camera cranes should assemble and/or operate these devices.

- When used, camera cranes should be inspected daily by qualified personnel (e.g., key grip, camera crane/dolly grip, vendor’s representative or other qualified personnel as determined by the Producer), following an inspection protocol supplied by the manufacturer/vendor. If components are missing, damaged or improperly fitted, the equipment should be removed from service. Missing or damaged components are to be replaced or repaired in accordance with the manufacturer’s/vendor’s procedures prior to the equipment being returned to service.

- Using the largest base that is practical increases the stability of the unit. The appropriate base for a crane is determined by the height, length and total load. Refer to the operating manual.

- The camera crane base should be on a flat and level surface, platform or track system capable of supporting the intended load. The weight of all personnel, equipment and the camera crane should be taken into consideration.

- The payload on the boom arm should not exceed that which can be balanced by the counterweight system supplied with the equipment. Additional counterbalance weight that is above and beyond that specified by the manufacturer/vendor should not be used. The manufacturer/vendor should be consulted regarding all extension configurations that are not explicitly specified in the operating manual.

- Seat belts are to be provided on all camera cranes where passengers are required for operation. Seat belts should be maintained in good condition, and used by all passengers.

- Pushing camera cranes across slopes or over uneven surfaces such as cables, speed bumps, or curbs can cause the unit to tip over.

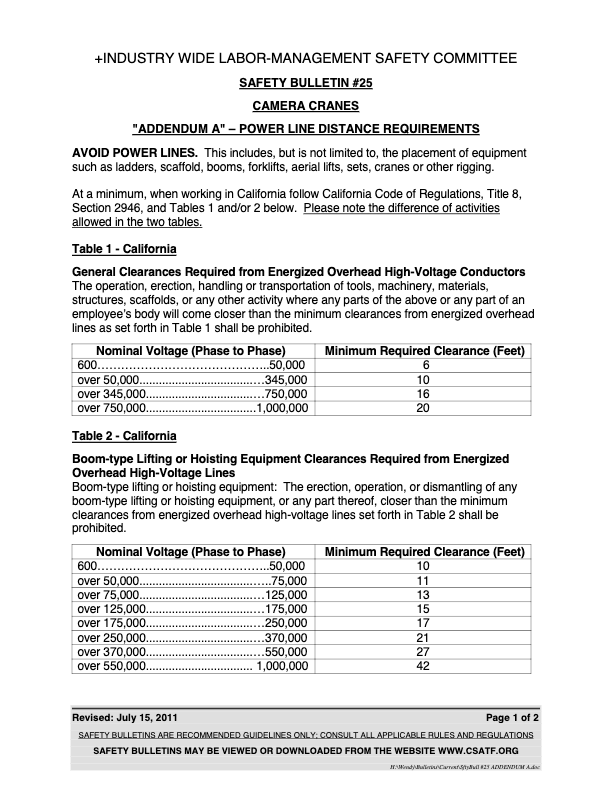

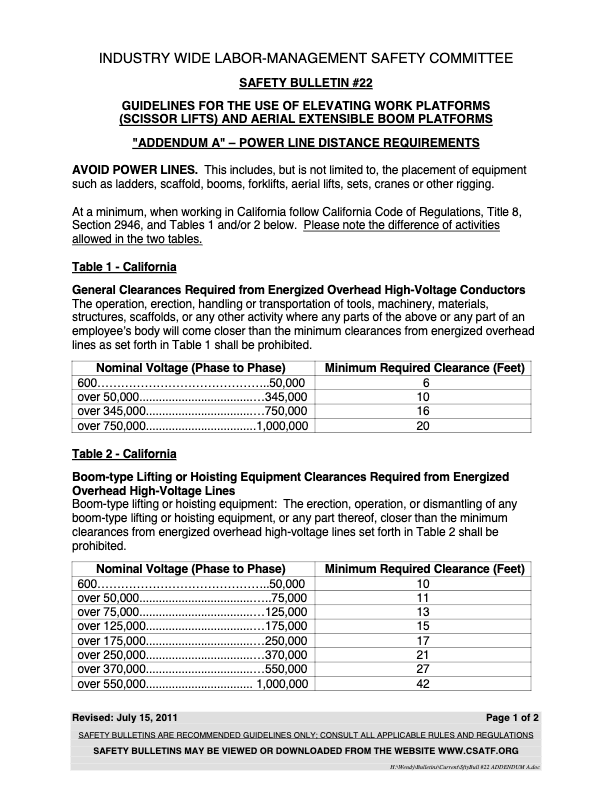

- When operating a camera crane, qualified personnel should ensure that there is adequate clearance for operation. Potential obstructions or hazards, such as power lines, helicopter rotors, fire sprinkler heads, etc. should be considered. Qualified personnel and the designated on-set safety coordinator should establish a safe operating zone. The designated on-set safety coordinator should maintain the safe operating zone. Special attention should be given to working around high voltage power lines.

Clearances Required from Energized Overhead High-Voltage Lines

| Nominal Voltage | Minimum Required Clearance (Feet) |

| 600 – 50,000 | 10 |

| 50,000 – 75,000 | 11 |

| 75,000 – 125,000 | 13 |

| 125,000 – 175,000 | 15 |

| 175,000 – 250,000 | 17 |

| 250,000 – 370,000 | 21 |

| 370,000 – 550,000 | 27 |

| 550,000 – 1,000,000 | 42 |

| Source: Title 8, California Code of Regulations, Subchapter 5, Group 2, Article 37, ‘2946 29 Code of Federal Regulations 1926.451 (F)(6) |

- If the camera crane is equipped with outriggers/stabilizers, follow the manufacturers’ instructions regarding their proper use. Care should be taken to ensure that the feet of the outriggers/stabilizers will not sink into soft soil or asphalt, otherwise, the unit may tip over. Adequate means of distributing the outrigger/stabilizer load should be used, when appropriate.

- It is recommended that special care be used when operating camera cranes on curved track. For example, excess speed could cause the unit to tip over.

- When moving a camera crane on or off the track, the arm weight should be reduced to allow for safe movement so as to reduce the chances of the unit tipping over. Consult manufacturer’s/vendor’s instructions.

- When stepping on or off of a camera crane, do so only after approval from the person operating the unit. Stepping off of a balanced camera crane without providing a counterbalance (e.g., another person to replace the weight) can cause the arm to elevate rapidly and possibly cause serious injury.

- Unattended camera cranes should be secured to prevent movement of the unit (e.g., adding or removing manufacturer-supplied weights from the weight bucket).

- When handling un-coated lead weights you should wear appropriate protective gloves and wash hands after use.

- When operating camera cranes, consideration should be given to wind, rain, extreme heat and cold and other atmospheric conditions, whether natural or manmade, which can affect the safe use of camera cranes.