Electrical Systems Safety Measures

1. Rigging a System

Use proper lifting techniques when lifting or moving heavy objects, such as cable or lighting equipment. Do not step directly on equipment such as cable. Cables can roll underfoot causing a slip or fall hazard.

The electrical system should be de-energized while it is being rigged. Before energizing the system, verify that the system is free from short circuits and/or crossed wires and verify all connections are properly mated.

2. Connecting Order of Single Conductors

All single conductor connections shall be made in the following order:

- Grounds (all AC, and on DC where used)

- Neutrals

- Phase Conductors (Hots)

Disconnect in the reverse order:

- Phase Conductors (Hots)

- Neutrals

- Grounds (all AC, and on DC where used)

All multi-pole connectors used on AC shall provide for “first make, last break” of the ground pole.

3. Color Coding

Portable cables and conductors shall be color coded in accordance with the NEC.

Neutral conductors shall be identified by marking at least the first 6 inches of both ends of each length of cable with white or gray.

Grounding conductors shall be identified by marking at least the first 6 inches of both ends of each length of cable with green or green with yellow stripes.

Phase conductors (hots) shall be identified by marking at least the first 6 inches of both ends of each length of cable with any color other than green, green with yellow stripes, white, or gray.

Commonly used colors for phase conductors (hots) on 120V systems are red, black and blue. Commonly used colors for phase conductors (hots) on 480V systems are brown, orange and yellow.

Where more than one voltage system exists within the same premises, each system conductor shall be identified by the system to which it is connected. This can be done by separate color coding, marking tape, tagging, or other equally effective means.

Where color coding is used to distinguish between different lengths or owners of cable, it must be done in a way that will not create confusion.

Caution should be used when using the color yellow as it may appear white under sodium lighting.

4. Devices and Cables

Cables and devices should be protected from foot and vehicle traffic damage.

Electrical distribution systems should be elevated in such a manner that they will not come in contact with running or standing water.

When it is necessary to have electrical distribution systems and devices which come into contact with water, such systems shall be designed and listed for use in water.

When lighting, electrical distribution, or any electrically powered equipment is used in close proximity to water or can make contact with water, the use of GFCI should be evaluated by a qualified person. This includes all areas where water hazards exist. When persons, wardrobe, props, or equipment are wet, the need for GFCI protection should be evaluated.

GFCIs should not be used on circuits where removal of power may create a greater hazard, such as airbags, decelerators, emergency egress lighting, etc.

Alligator clips or clamps shall not be used in conjunction with any electrical system or equipment.

Two-wire, non-polarized, DC-plugging boxes, paddle plugs, and porcelain boxes are not permitted on AC systems. This applies even with the use of an external ground.

All gang boxes supplied by a connector plug with an ampere rating higher than the receptacles in the gang box shall contain fuses or circuit breakers sized according to the ampere rating of those receptacles.

All AC multi-pole connectors shall be grounded and polarized.

All cable shall be listed by an approved testing laboratory. Only types “G,” “W,” or Flexible Stage and Lighting Power Cable (EISL, SC, SCE, SCT) are acceptable for single-conductor feeder cables.

Single-conductor connectors used on phase conductors and neutrals shall be connected to the conductors by means of solder, set-screw, or crimping. Flexible cords and cables shall be connected to devices and to fittings so that tension is not transmitted to joints or terminals.

Equipment Grounding Conductor connection devices or fittings that depend solely on solder shall not be used.

5. Guarding of Energized Parts

Any exposed or non-insulated part of the distribution system must be considered as energized until verified otherwise. and protected from accidental contact. Any point of danger, including the arc flash boundary, should be protected, shielded or barricaded to prevent any possible entry by unauthorized persons or objects.

6. Portable and Vehicle Mounted Generators

Approach to exposed connections on portable and vehicle mounted generators should be physically restricted or barricaded to non-qualified persons. Any

generator with exposed busbars or other energized parts should be guarded as described in Section 5 of this document.

Read thoroughly any operational manuals and complete appropriate forms and logs provided with the generator. Only a qualified operator designated by the employer shall operate a generator.

A fire extinguisher specific for the generator unit must be present and readily accessible outside the generator enclosure. Refer to studio policy on employee use of fire extinguishing equipment.

The generator should have as much open space as possible on all sides to allow maximum ventilation and minimum interference. It is important that all generating sets be protected from the elements and from unauthorized access.

The following precautions must be taken when re-fueling the generator:

- The generator must be off.

- A listed fuel nozzle must be used to prevent static electricity build-up.

- Connect a ground bond from the frame of the re-fueler to the frame of the generator.

Make sure exhaust fumes are ventilated away from enclosed areas, personnel, and air intake ducts, such as trailers and buildings. Be aware of hot surfaces when working around a generator.

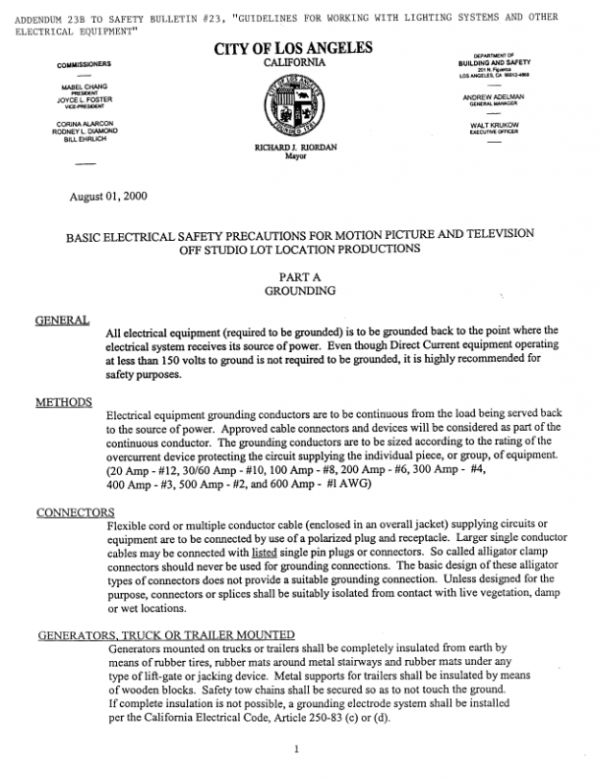

Portable AC generators shall comply with the NEC, Section 250.34.

Vehicle mounted generators mounted on the same frame as the equipment they are supplying shall be completely insulated from earth by means of rubber tires, rubber mats around metal stairways and rubber mats under any type of lift gate or jacking device. Metal supports for trailers shall be insulated by means of wooden blocks. Safety tow chains shall be secured so as to not touch the ground. If complete insulation is not possible, a grounding electrode system shall be installed per the NEC, Section 250.52.

Earth grounding of portable generators shall comply with applicable sections of Article 250 of the NEC as determined by the AHJ.

Portable generators that produce both AC and DC are not producing pure direct current, and must not be used in DC mode around water. GFCIs will not function when supplied by DC.

7. Generator Grounding Connections

Generators shall be grounded in accordance with Article 250 of the NEC.

Fire hydrants, interior metal pipes, fixtures, standpipes or metal frames of buildings SHALL NOT BE USED as a grounding connection for mobile generators, unless approved by the AHJ.

8. Portable Transformers

Portable transformers shall be used, grounded, and bonded in accordance with the NEC, all applicable Federal, State and Local laws and regulations, and the determinations of the AHJ.

The ground of all transformers shall be connected to the ground of the supplying power source.

Proper clearance and ventilation shall be maintained around the transformer. Verify the ground is bonded to the neutral inside the transformer.

9. Bonding of Separately Derived Power Sources

The grounds of separately derived power sources must be bonded together when located within 20 feet of each other or when one power source supplies equipment that may come within 20 feet of equipment supplied by another power source. When filming on interior sets this distance may be reduced to 12 feet.

When supplemental power is provided to a building (where allowed) and/or is supplying additional power inside the building, the ground of the supplemental power source must be bonded to the building’s grounding electrode system.

The size of the bonding conductor(s) shall not be less than that given in NEC Table 250.66.

10. Grounding Direct-Current Equipment

DC-supplied equipment operating over 150 volts shall be grounded. Care should be taken to provide a barrier, either of material or space, between grounded and non-grounded devices.

When using 2-wire, ungrounded equipment on DC, verify there are no grounded metal surfaces, such as green beds, pipe grids or scaffolding, within 12 feet of the DC equipment.

11. Grounding Alternating-Current Systems and Equipment

All AC-supplied systems and equipment used by the motion picture and television industry shall be grounded.

All AC-supplied equipment shall have all non-current-carrying metal parts grounded by a continuously connected, equipment-grounding conductor back to the source of power. This conductor shall be sized according to NEC Table 250.122 .

12. Connecting to Premises/House Electrical Power Source (tie-in)

Connecting to a premises/house electrical power source (tie-in), such as a panel board or switchboard, can create the risk of a serious or fatal accident. Such connections shall only be made by a qualified person. Before performing this work, check with the NEC, all applicable Federal, State and Local laws and regulations, and the determination of the AHJ.

At a minimum, the AHJ will require that a qualified person possess:

- The skills and techniques necessary to distinguish exposed live parts from other parts of electrical equipment.

- The skills and techniques necessary to determine the nominal voltage of exposed live parts.

- The knowledge of working clearance distances specified for various voltages to which personnel will be exposed, including arc-flash and shock-protection boundaries.

- The knowledge of lockout/tagout procedures and access to lockout/tagout equipment.

- The knowledge of proper use of personal protective equipment, insulating and shielding materials, and insulated tools.

- The knowledge to not wear jewelry, conductive clothing, and other unsuitable synthetic apparel when working on or around electrical equipment.

- The knowledge to select, inspect and use appropriate electrical test equipment.

- The necessary credentials and/or the ability to obtain required permits.

- The knowledge to perform proper emergency procedures.

Unless the electrical system of a building has been properly de-energized, locked out/tagged out, and verified to be de-energized, assume the electrical panel is energized.

Energized parts with which a person could make contact must always be de- energized, unless:

- The de-energization of the system is not possible, due to the design of the equipment.

- The de-energization of the system will cause an additional hazard, such as deactivation of emergency systems.

- The electrical system supplies circuits that form an integral part of a continuous process that would need to be completely de-energized in order to work on the panel or circuit.

When unable to de-energize the circuit, and where the possibility exists of personnel coming in contact with energized equipment, equipment shall be properly insulated as described in Section 5 of this bulletin.

The use of an in-house “Energized Electrical Work Permit” system as described in NFPA 70E is recommended to determine the necessity of the energized work and to ensure that all parties involved are aware of the hazards associated with connecting to an energized power source, including potential hazards to other systems that are connected to the power source.

Connecting to an energized system is strongly discouraged. If work on energized electrical equipment is necessary, at a minimum, you must follow the arc-flash hazard-analysis label (if present) to determine the hazard/risk category and associated PPE required to prevent injury or death. In lieu of a label, consult and follow NFPA 70E Table 130.7(C)(9) requirements.

Remember, always consider exposed electrical parts to be “energized” until you have verified they have been de-energized and locked out/tagged out.

Obtain an electrical permit from the appropriate AHJ before such work is done. Any connection to a premises/house electrical power system shall be performed by a qualified in-house electrician. If a qualified in-house electrician is not available, the work shall be performed by a qualified electrical contractor or other qualified person.

Prior to a qualified person connecting to a premises/house electrical power system, the following requirements, among others, must be adhered to:

- Determine if the electrical system voltage is compatible with the equipment to which it will be connected.

- Calculate the electrical panel’s existing maximum ampere load to determine if the remaining capacity is sufficient for the additional equipment being connected.

- Use a properly sized circuit breaker or fusible disconnect switch to connect a distribution system to the premises/house electrical power system.

- The rated interrupting capacity of the circuit breaker or fuses must meet the available interrupting capacity at the point of connection to the premises/house electrical power system.

- Use only approved lugs or devices to connect to the panel bus.

- Never use “Alligator” type clamps.

- Never connect ahead of the main circuit breaker, fuse box, or meter.

- If required, obtain a permit to remove a panel cover.

- Use suitable barriers, partitions, or other means to limit access to the connection to protect against accidental contact with energized parts and unauthorized entry into the arc-flash boundary by unauthorized persons or objects.

- Replacement of all panels, covers and screws must be done by a qualified person immediately after disconnecting from the premises/house electrical power system.

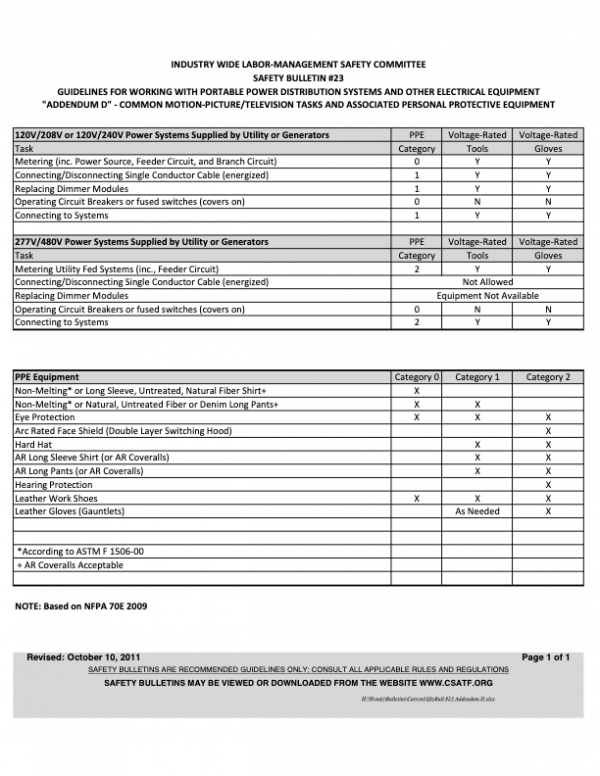

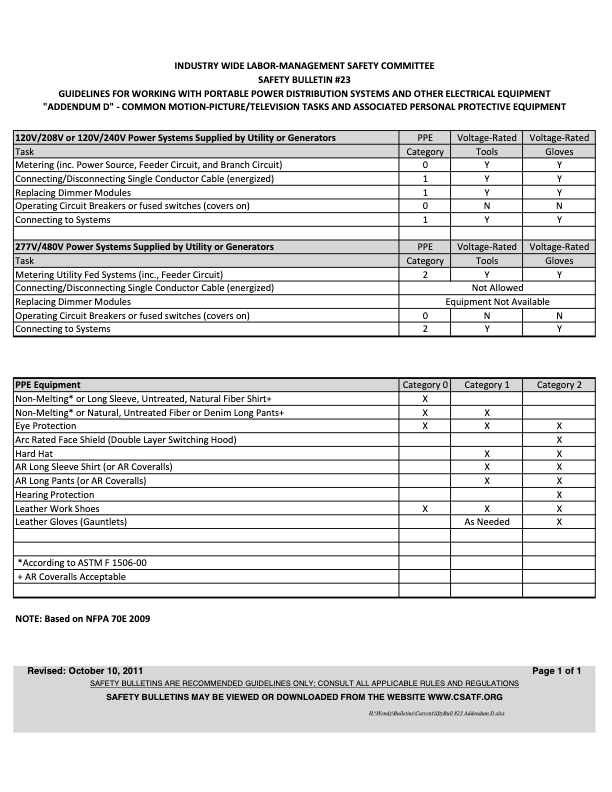

13. Personal Protective Equipment (PPE)

All persons working on or near energized electrical equipment shall wear PPE appropriate for the level of electrical hazard to which they are exposed. This PPE may include non-melting, long-sleeved shirts and long pants, or other Arc Rated (AR) clothing, and closed-toed, nonconductive-soled shoes and Safety Glasses. Garments made from synthetic materials not manufactured specifically for electrical work, such as polyester and nylon, are not suitable to protect from electrical hazards.

For an extended list of common motion-picture/television tasks and associated PPE refer to Addendum D. This addendum is based on NFPA 70 E and will be updated as warranted.

Refer to NFPA 70E Tables 130.7(C) (9) and (10) for a full list of tasks performed

on energized equipment, the associated hazards/risk categories, and required PPE.

14. Emergency Response

If an electrical accident occurs, notify emergency medical personnel and activate the Emergency Action Plan.

An Emergency Action Plan should include the following items:

- Location, method and any necessary tools required for emergency power disconnection

- Emergency Medical Services on hand or readily available with working means of contact

- Exact location of where the work is being performed

- Identification of CPR Trained Personnel

- Location of available AEDs

do not approach any electrical accident until you have been notified by qualified personnel that it is safe to approach.

Properly secure the accident area while maintaining a safe distance to prevent the possibility of additional victims.

DO NOT touch or approach a victim of electric shock while he or she is being shocked. If safe to do so, turn off the power.

Trained personnel should follow proper procedures for Cardiopulmonary Resuscitation (“CPR”) and Automated External Defibrillator (“AED”) use.

Since the possible effects of electrical shock can manifest hours after the event, any victim of electric shock must be evaluated by a qualified medical professional.