Safety Bulletin

Guidelines

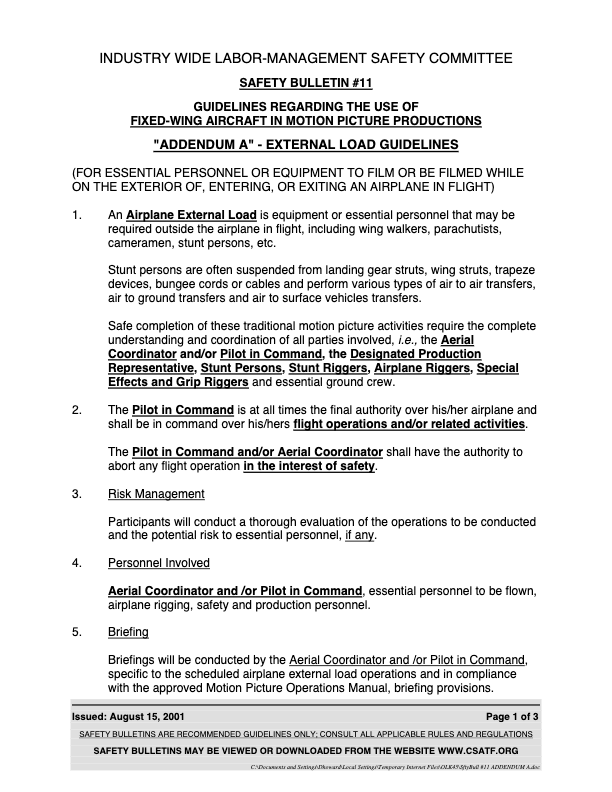

- Helicopter External Loads: Traditional helicopter motion picture activities include stunt persons transferring, air to air between helicopter and airplane, air to ground between surface vehicles or persons, Rappelling, Fast Roping and many other scenarios where essential personnel and equipment may be required outside the helicopter. Stunt persons and cameramen are often called upon to stand upon or hang from landing gear skids, cargo hooks, trapeze devices, bungee cords, cables, ladders, long-lines, etc. Safe completion of these operations require the complete understanding and coordination of all parties involved, i.e., the Aerial Coordinator and/or Pilot in Command the Designated Production Representative, Stunt Persons, Helicopter Riggers, Special Effects and Grip Riggers and essential ground crew.

- Pilot in Command: The Pilot in Command is at all times the final authority over his/her airplane and should be in command over his/hers flight operations and/or related activities. The Pilot in Command and/or Aerial Coordinator should have the authority to abort any flight operation in the interest of safety.

- Personnel Involved: Aerial Coordinator and/or Pilot in Command, essential personnel to be flown, helicopter rigging, safety and production personnel.

- Briefing: Briefings will be conducted by the Aerial Coordinator and/or Pilot in Command, specific to the scheduled helicopter external load operations and in compliance with the approved Motion Picture Operations Manual, briefing provisions.

- Risk Management: Participants will conduct a thorough evaluation of the operations to be conducted and the potential risk to all personnel, if any.

- Communication: Communication must exist at all times between the pilot, the stunt person(s) and other essential personnel. This can be accomplished utilizing radios, intercoms, or pre-briefed visual signals. Additionally, the pilot must be able to maintain visual contact with the stunt person(s) and other essential personnel in the event of lost communications. If visual contact cannot be maintained a third party, who can maintain visual contact, will be used. This person may be on board the helicopter, on the ground, or in another aircraft.

- Attaching Methods and Devices: All personnel must be attached to the aircraft while in flight, unless those persons are performing an essential function outside the aircraft requiring them to depart the aircraft in flight, e.g. parachuting or transfers. Seat belts, cables and safety lines will be attached to existing helicopter hard points, seat belt attach points, cargo tie down points, airframe bridles, or other suitable airframe locations. Attaching devices, i.e., cables, carabineers, braided nylon climbing rope, nylon straps, steel clevises, body harnesses, etc., are normally provided by the special effects, grips and stunt personnel. All of the above attaching devices must have load ratings established by the manufacturer in compliance with various industry and government specifications and established Motion Picture safety guidelines. A person will never be attached to a load release device.

- Parachutes: If parachutes are to be utilized, they must be of an FAA approved type, must have been packed and certified within the preceding 120 days. While wearing a parachute, the parachutist must not be attached to the aircraft, except during takeoff and landing! An accidental parachute opening while attached to the Helicopter could have a serious negative effect on the aircraft and parachutist.

- Rappelling:

- Rappelling Pilot Qualifications:

- Possess a letter of competency or an appropriate logbook entry indicating compliance with the pilot provisions of 14 CFR Part 133; or

- Be qualified on the basis of previous experience and safety record; or

- An actual flight, demonstrating the pilot’s knowledge and skill regarding repelling operations.

- Rappeller Qualifications:

- Rappellers (Stunt Persons) and Spotters, will be required to demonstrate their rappelling ability during required familiarization flights.

- The Aerial Coordinator and / or Pilot in Command will have the authority to withhold approval of any rappeller (Stunt Person) or spotter.

- Rappelling Pilot Qualifications:

- Rappelling Special Provisions: The Aerial Coordinator or the Pilot in Command has the authority to cancel or delete any activity or event, if in their opinion, the safety of persons or property on the ground, or in the air, is at risk or if there is a contravention to the provisions of their Motion Picture Waiver.

- Weight and Balance: Due to the nature of helicopter, external loads involving essential persons or equipment, diligent review and compliance with the manufacturer’s weight and balance data is required. Prior to the initial flight of a new external load configuration, hovering test should be conducted to verify the lateral and longitudinal centers of gravity and maximum allowable helicopter weight.

- Rappelling Pilots Check List:

- Aircraft:

- Load bearing capacity and method of securing of all attaching devices related to the external load.

- Verification of load bearing capacity and anticipated loads on the airframe, attach points to be utilized.

- Accomplish Weight and Balance of the external load, including, if necessary, the possible release or departure of the external load.

- Verify operation of load release device, if any. Note: A person will never be attached to a load release device.

- Personnel:

- Verify that only essential personnel are onboard the aircraft.

- Confirm essential personnel specific duties and responsibilities.

- Communications check, audio, and visual signals.

- Review emergency procedures specific to the external load operation with all essential personnel.

- Review potential risk, if any, with the essential personnel.

- No essential personnel may participate in the helicopter external load operation unless they have read, understood, and agreed to comply with the conditions of the Waiver Holders, Certificate of Waiver and its special provisions, if any.

- Rappel Equipment:

- Rope size, appropriate to the rappel (friction) device being used, will be required for all Rappel operations.

- Rope strength, for each specific load, a safety factor of 10:1 between the strength of the weakest piece of attaching equipment and the load to be carried, will be utilized. The absolute minimum tensile strength of any Rappel rope will be 5000 lbs. tested to NFPA and/or other regulatory standards.

- Ropes will have a rubber jacket or other appropriate edge protection to give protection on door sills and edges when using floor attach points.

- Carabineers, steel, or aluminum must have a minimum tensile strength of 5000 lbs. be a locking type, and be tested to NFPA and/or other regulatory standards.

- Cutting devices, knifes, cable cutters, etc. sufficient to cut any attaching device will be provided to the spotter or safety persons for use in an emergency.

- Rappel ropes will have a minimum of two airframe attach points per rope, with test strengths equal to or greater than 5000 lbs. per rappeller.

- Aircraft:

- Fast Roping:

- Fast Roping Pilot Qualifications:

- Possess a letter of competency or an appropriate logbook entry indicating compliance with the pilot provisions of 14 CFR Part 133; or

- be qualified, based on previous experience and safety record; or

- an actual flight, demonstrating the pilot’s knowledge and basic skills required to conduct Fast Rope vertical reference type operations.

- Fast Rope Personnel Qualifications:

- Fast Ropers (Stunt Persons) and Spotters, will be required to demonstrate their ability during required familiarization flights.

- The Aerial Coordinator and/or Pilot in Command will have the authority to withhold approval of any Fast Roper (Stunt Person) or spotter.

- Fast Roping Special Provisions:

- The Aerial Coordinator or the Pilot in Command has the authority to cancel or delete any activity or event, if in their opinion, the safety of persons or property on the ground or in the air is at risk, or if there is a contravention to the provisions of their Motion Picture Waiver.

- Fast Rope Equipment:

- Airframe attach points must be of an FAA approved type, providing sufficient lateral arm to extend beyond the outermost portion of the helicopter airframe and be certified for a 10:1 weight bearing capacity.

- Rope size, appropriate to the rappel (friction) device being used, will be required for all fast rope operations.

- Fast Rope strength, for each specific load, a safety factor of 10:1 between the strength of the weakest piece of attaching equipment and the load to be carried, will be utilized. The absolute minimum tensile strength of any Fast Rope will be 9000 lbs. and have a high melting point as designed for fast rope/rappelling operations.

- Cutting devices, knifes, cable cutters, etc. sufficient to cut any attaching device will be provided to the spotter or safety persons for use in an emergency.

- Fast Ropes will have a minimum of two airframe attach points per rope and have the appropriate rated strength.

- Fast Roping Pilot Qualifications:

- Weight and Balance: See Paragraph 11.

- Pilots Check List: See Paragraphs 12 A B C.