The following procedures are recommended for all water work, including, but not limited to ponds, rivers, lakes, swamps, bogs, oceans, pools, and tanks, or any other unduly wet work environment.

Identification of potential contaminants or hazards

Know as much as you can about the body of water you’re working on or in, including its natural hazards and animal life. The Production Company, Location Manager or the Safety Coordinator should have all relevant information.

The Producer should identify and make known prior to actual filming, all available knowledge regarding currents and natural or man-made hazards, including sub-surface objects, underwater life, and contamination. Upstream activities, such as dams, waste disposal sites, agriculture, chemical plant dumping sites, flash flood dangers, etc. should also be evaluated. If a potential safety hazard is found to exist, the Producer should take appropriate steps to mitigate the hazard.

Prior to personnel entering a body of water, a determination should be made that the water quality meets the applicable regulatory standards for recreational full body contact. Samples of the water should be taken and analyzed for any potential environmental concerns and/or health hazards. If it is determined that a body of water is contaminated or hazardous, the contamination or hazard should be neutralized or the site shall be avoided.

Extreme care should be taken regarding dangerous marine life, including reptiles.

All personnel should be advised to keep all potential contaminants away from the water, including paints, thinners, repellents, gasoline, oils, etc.

Notifying and protecting personnel

All personnel scheduled for water work shall be notified in advance via the Call Sheet. Personnel who are uncomfortable working in or around water should notify their supervisor prior to that day’s call.

All personnel working in or around water shall be provided with the appropriate water safety devices, such as life vests or other water safety gear when appropriate. (See Safety Bulletin: Recommendations for Diving Operations.)

When necessary, the Producer should implement a plan to account for personnel in the water, such as a “buddy” or a check in/check out system.

The Producer should take steps to prevent hyperthermia (elevated body temperature) and hypothermia (reduced body temperature).

Provisions for post-immersion washing should be available.

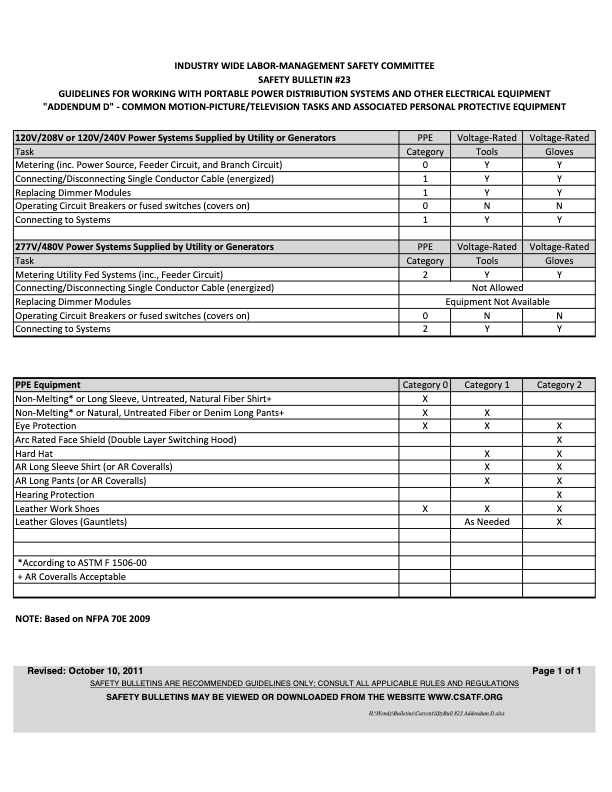

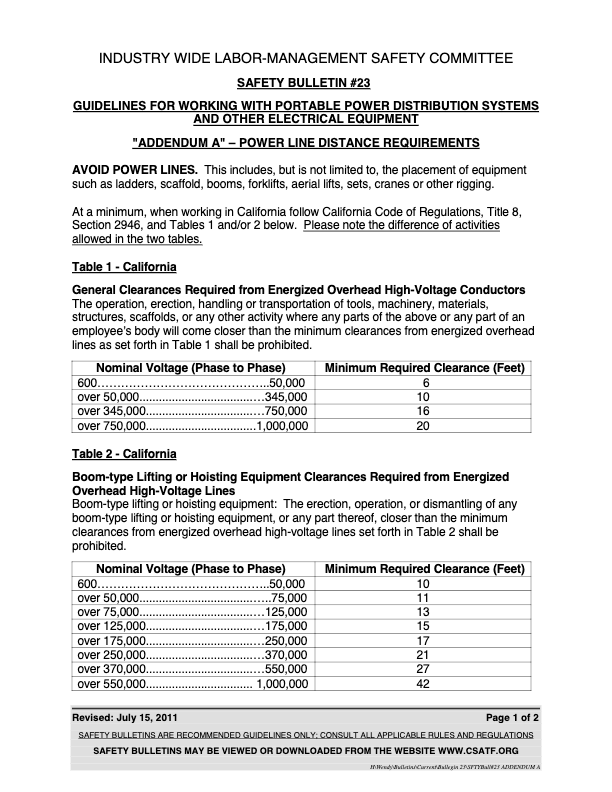

Lighting and electricity

Special care must be used whether AC or DC electricity is used in or around water. All electrical cables and lights in close proximity to water shall be properly secured to prevent tipping and falling. All wiring, electrical equipment and devices that will, or may be, subject to a submerged condition should be approved for underwater use, be watertight, have no exposed live connections and be constructed such that there is no shock hazard under any likely conditions of use. All applicable provisions of the National Electric Code should be followed. Local regulations may be more restrictive and should be consulted.

When lighting, electrical distribution, or any electrically powered equipment is used in close proximity to water or can make contact with water, the use of GFCI should be evaluated by a qualified person. This includes all areas where water hazards exist. When persons, wardrobe, props, or equipment are wet, the need for GFCI protection should be evaluated.GFCIs should not be used on circuits where removal of power may create a greater hazard, such as airbags, decelerators, emergency egress lighting, etc.

All electrical connections should be made by, or under the supervision of, a qualified person.

Other considerations

Safety lines, nets, watch safety personnel and/or divers should be used when filming in rivers or other bodies of water where potentially hazardous conditions could exist (e.g., swift currents, thick underwater plant life, or rocks).

When necessary for personnel to work in fast-moving rivers, downstream safety pickup personnel and safety equipment should be stationed for downstream emergency rescue.

When using watercraft, be aware of load and rider capacity limits. Only required personnel should be on watercraft; all others should remain on land. (See Safety Bulletin: Guidelines for Boating/Watercraft Safety.)